Just tested the Shelly 1PM

Findings:

– you NEED to use the internal switch / you can’t bypass it (if you want to measure)

– set „Settings -> Power on default Mode“ to „ON“ if you use it inline

– the measurement is not as exact as the 3EM, as it allways assumes 220V for it’s calculation (maybe the 1EM is better)

– measurement can be ajusted… a bit… get a Voltage reeding „Your Voltage/220v=0,x-1,x“

(In my case 235v/220v=1,06) [yes, I’m getting 235v at the plug]

– the measurement correction you find in „Settings -> Power Consumption Correction“

— Please note: your voltage changes over the day & if you set the line under load, volage will drop, so consider measuring under load.

– for that connect:

— MAINS N to N

— MAINS L to L1

— O to your Load/Production

– you can connect a Switch between L & SW -> „Settings -> Power on default Mode“ to „Switch“ so you can use a switch to operate the internal one (if you have the usecase for that… you know it)

– the Internal Switch is… next to useless for me, I can’t use it to trigger a seperate contactor for „loadswitching“

You can get better hardware (1EM/3EM) for more money (50/130€) but if you are fine with this approximate values… ~16€ is pretty good for the value you get.

Archiv der Kategorie: in English

[EN] 4 years old APC Back UPS PRO USV 900VA (BR900G-GR)

On November 29,2013 I had finally bought a UPS. Previously, my first server (Core2Quad) had been in continuous operation for 4 years, with only two interruptions due to a power failure. However, this was twice too much for me, especially since the Intel „fake“ RAID didn’t want to get into gear again and again. This was especially when I was at school or at work and had to retrieve data for the training.

IT problems always arise when you can use them least.

So server, switch & router to the UPS and go. I hadn’t considered other factors like temperature at that time, because everything was in the attic, so it wasn’t „too cold / too warm“ or also: something between 14°-36°C – is already working….

A year ago, the UPS then migrated to the living area, where I had to switch it more often. In this case, the battery level usually dropped directly to 40% and then ran a little bit. (see measurement results)

So we needed a new battery and we all know where to get RBC123 (please use preferred suppliers here).

APC promises the following values ex works:

| Load | Runtime |

| 540W (100%) | 5m |

| 270W (50%) | 16m |

| Expected battery life | 3-5 years |

This improved the runtime accordingly.

Measurement results:

old battery

| Load | Expected runtime | real runtime |

| 218W | 23m | 6:22m |

| 383W | 0m | 2:26m |

new battery

| Load | Expected runtime | real runtime |

| 216W | 23m | 20:28m |

| 387W | 2m | 7:10m |

I have to say that I don’t have the UPS on my PC, so I didn’t tell her that she got new batteries.

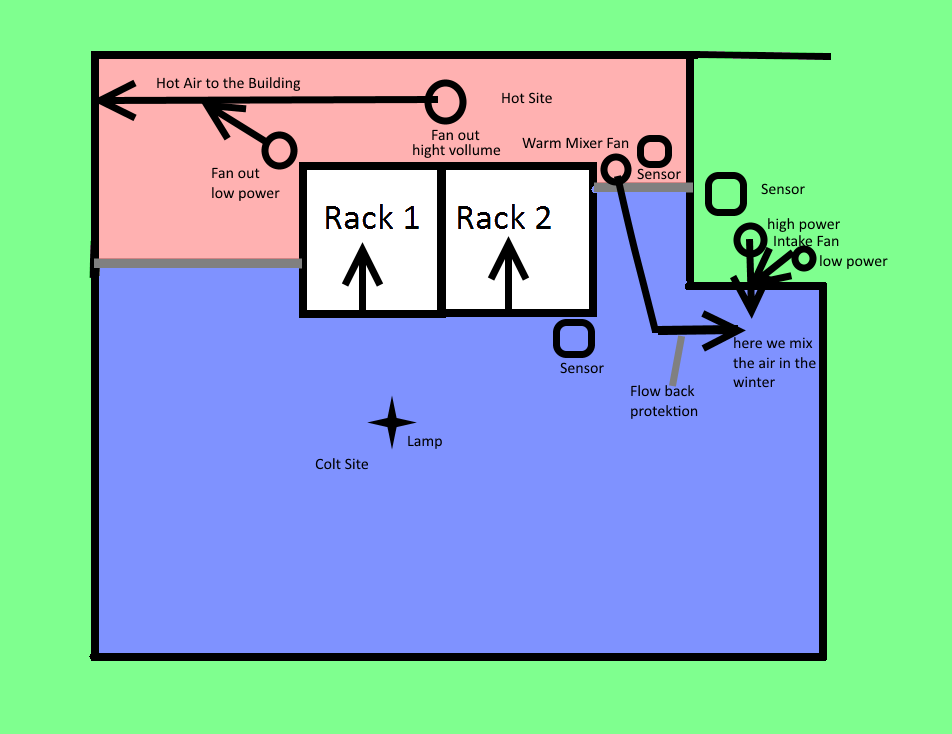

Comment: My Cool Data Center, is getting Hot, Need to Improve on That – 527

This is an comment so Morten Video „My Cool Data Center, is getting Hot, Need to Improve on That – 527“.

Hi Morten,

I’ve ask my colleagues from the datacenter expert team how they would cool such a small 8-20m² colocation room.

They see the following as essential:

do:

– filter the air (like an K&N filter from the car tuning store)

– mesure or calculate the air flow of your servers

– use a return flap on the intake and outtake, to have a defined airflow

– monitor temperature and humidity

– use A & B feed with ups and genset (they build Tier II to IV Datacenters the hole day)

– use surveillance, access control, intrusion detection (and allso high secure ones)

– use redundancy all time n+1/2 (WTF – for at home?!?)

don’t do:

– use high pressure intake fans, otherwise the fans in the server will become generators and that would damage the Servers over time

so one fan that push out the hot air is just fine

– short circuit the air typ’s

Solution:

They told me tho use an PLC to controle the system like a Siemens Logo.

My idea was to use an raspi or aduino with

2/3x DHT22 (behind the rack, in front of/in the room, outside)

5V Relay board 4 or 8 channels to turn the fan’s on and off to reduce power consumption (easy way) or if possible control fan speeds

some scripts, wiringPi, lol_dht22

Here is an shot overview of my plan:

And here the simple script to check temperature and humidity, to make a switching decision:

#!/bin/bash

#

# Script mit schaltbefehlen je nach Luftfeuchtigkeit und Temperatur

# Script to controll air exchange

# Variablen

#humi=$(sudo /var/www/loldht 7 | grep -i "humidity" | cut -d ' ' -f3)

humi=$(sudo /var/www/loldht 7 | grep -i "humidity" | cut -d ' ' -f3 | cut -d '.' -f1)

#temp=$(sudo /var/www/loldht 7 | grep -i "temperature" | cut -d ' ' -f7)

temp=$(sudo /var/www/loldht 7 | grep -i "temperature" | cut -d ' ' -f7 | cut -d '.' -f1)

# hier Vergleichswert einlesen

# fill variables with data

humi_max=70

temp_max=35

temp_mode25=25

temp_mode24=24

temp_mode23=23

# Luftfeuchtigkeit - humidity 70% Max.

if [ $humi -ge $humi_max ];

then

/home/pi/schalter/r1-on.sh

/home/pi/schalter/r2-on.sh

sleep 600

/home/pi/schalter/r1-off.sh

/home/pi/schalter/r2-off.sh

else

# Temperatur 35° Max.

if [ $temp -ge $temp_max ];

then

/home/pi/schalter/r1-on.sh

/home/pi/schalter/r2-on.sh

sleep 10

/home/pi/schalter/r1-off.sh

/home/pi/schalter/r2-off.sh

else

# Temperatur 25° Max.

if [ $temp -ge $temp_mode25 ];

then

/home/pi/schalter/r1-on.sh

/home/pi/schalter/r2-on.sh

sleep 5

/home/pi/schalter/r1-off.sh

/home/pi/schalter/r2-off.sh

else

# Temperatur 24° Max.

if [ $temp -ge $temp_mode24 ];

then

/home/pi/schalter/r1-on.sh

/home/pi/schalter/r2-on.sh

sleep 4

/home/pi/schalter/r1-off.sh

/home/pi/schalter/r2-off.sh

else

# Temperatur 23° Max.

if [ $temp -ge $temp_mode23 ];

then

/home/pi/schalter/r1-on.sh

/home/pi/schalter/r2-on.sh

sleep 3

/home/pi/schalter/r1-off.sh

/home/pi/schalter/r2-off.sh

else

echo "nö"

#Ende der IF's

fi

fi

fi

fi

fi

#

# Test

echo "Luftfeuchtigkeit " $humi # > /home/pi/temp/demo

echo "Temperatur " $temp # >> /home/pi/temp/demo

or the download with all my tapstops: